MIT Develops New Material

Engineers from MIT, Caltech, and ETH Zürich have published a new study looking at “nano-architected” materials, which are made up of microscopic structures that are carefully structured. The material could be useful for lightweight armour, protective coatings, blast shields, and other impact-resistant materials, according to the researchers. The ultralight material is made of nanometer-scale carbon struts, which make the material very durable and mechanically resilient.

Material tested Through Supersonic Micro-Particles

The material was put to the test by firing supersonic micro-particles at it by MIT engineers. Despite being thinner than the diameter of a human hair, the material kept the tiny particles from tearing through it. The novel material is more efficient at absorbing impacts than steel, Kevlar, aluminum, and other impact-resistant materials of equivalent weight, according to the researchers. According to lead researcher Carlos Portela, the new material would be more effective at stopping a projectile than Kevlar of the same mass.

Lighter and Harder Material

The new material might be developed to be lighter and harder than existing regularly used materials if mass-produced on a massive scale. The nanometer-scale patterns that the nanoarchitecture material is patterned with can have unique features depending on how they are structured, such as extraordinary lightness and robustness. According to Portela, researchers only know how these materials respond under a slow-deformation regime. It’s thought that a lot of practical utility will be in real-world applications where nothing deforms slowly.

Material Testing

His team intended to investigate the materials under faster deformation situations, such as high-velocity collisions. Caltech researchers used two-photon lithography to create a nanoarchitecture material. A high-powered laser is used to harden minute shapes in a photosensitive resin in this method. A tetrakaidecahedron is a repeating design created by researchers.

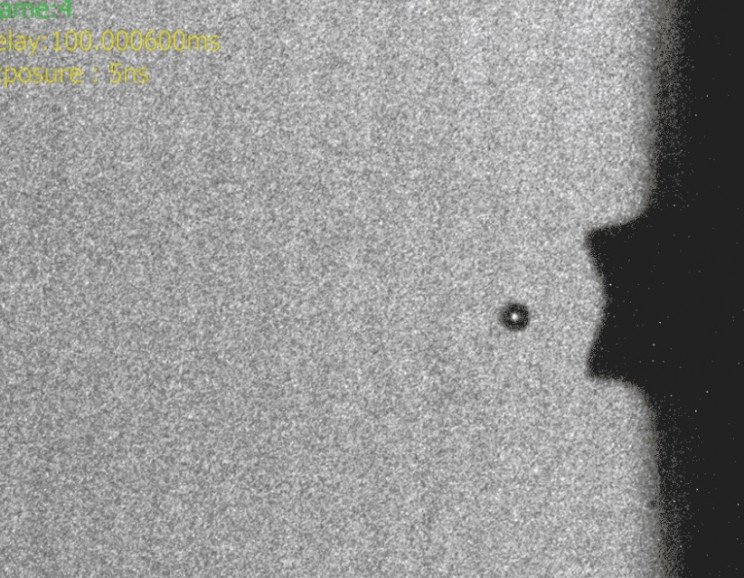

Researchers rinsed away the residual glue after patterning the construction. The structure was then placed in a high-temperature vacuum furnace to convert the polymer to carbon, yielding a lightweight, architected carbon material. The scientists used laser-induced particle impact experiments at MIT to test the material under high deformation in a microparticle impact experiment. Silicon oxide particles with a diameter of 14 microns were used in this experiment.

The particles were modified to velocities ranging from 40 to 1100 meters per second, with anything supersonic exceeding 340 metres per second. The investigations reveal that the material can absorb a significant amount of energy while particles are unable to travel through it.