After using and manufacturing chipsets from silicon for nearly 50 years, researchers with the help of Arm and PragmatIC have now created the first chipset made out of plastic as a base material. The 32-bit PlasticArm Chip (microprocessor) concept is based on ARM’s Cortex-M0+ chipset design and supports the ARMv6-M architecture. This development will surely allow a new era where these truly bendable, flexible microchips can be used everywhere from clothes to water bottles, claims researchers.

About PlasticArm Chips

As earlier, we have used silicon-based chips for the past 50 years as it is the 2nd most common element on earth and as it is capable of working as an energy conductor or as an energy insulator depends upon its implementation. But Arm and PragmaIC came up with flexible plastic arm chips.

Initially, the Arm showed the flexible PlasticArm chip in 2015 but there was no functional design at that time. The help of a new manufacturing system and improvisations in technology helps Arm in fulfilling the functional design of PlasticArm Chips in October 2020.

With the era of plastic arm chips, it doesn’t mean that they are going to replace silicon-based chips as they have their advantages in terms of performance, density, and power efficiency. TFT or thin-film transistor-based chips only widen the scope of processors to use in potential applications.

Specifications of PlasticArm Chip

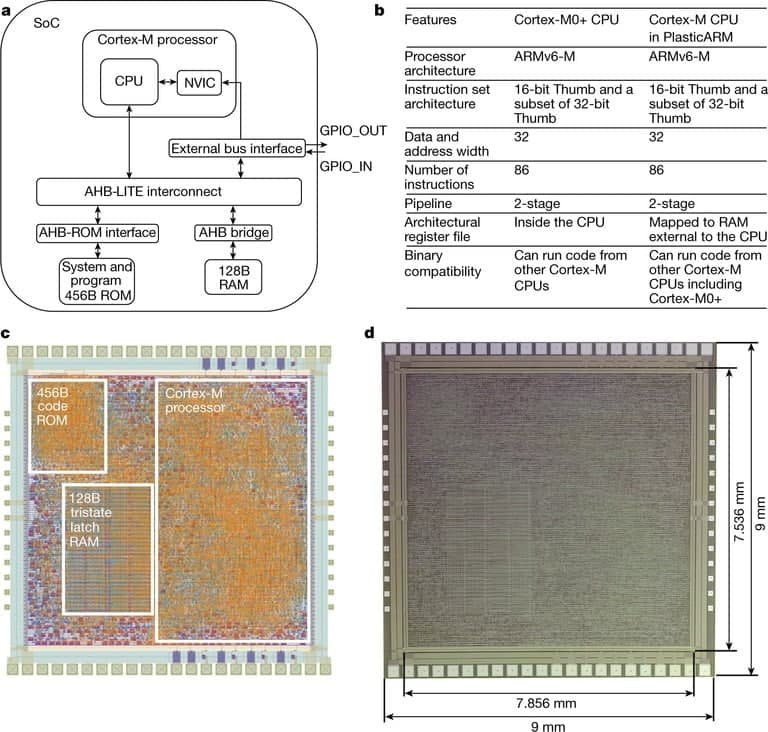

As mention at the start, the PlasticArm Chip is a 32-bit processor based on ARM’s Cortex-M0+ chipset design and supports the ARMv6-M architecture integrated with around 18,000 logic gates, a processor, memory, controller, and inputs and outputs.

The 32-bit PlasticArm Chip has 128 bytes of RAM and 456 bytes of storage. And ARM claims in the blog post that the PlasticARM system on a chip (SoC) is capable of running programs from its internal memory and its hardware is twelve times more complex than previous flexible electronics.

The researcher builds the most complex flexible integrated circuit with metal-oxide TFTs (Thin-Film-Transistors) which enables processors to be built on flexible surfaces. This would also allow to create chips cheaper and use them in uniques ways.

Applications

The researchers mentioned only a few applications of flexible chipsets that are bottles, food packages, garments, wearable patches, and bandages. After advancement in PlasticArm chips, we could have smart milk jugs that tell about your milk has soured or we can monitor vitals through a wearable patch. The key component of this innovation is a cost that would allow the adaption of plastic chips to everyday objects.

PlasticArm Chip aims to provide flexible chips and cheap to be used every day cost-effectively. This would remove the limitations of silicon-based chips. Although they are not replacing silicon chips as they have better performance, density, and power efficiency.

However, researchers in their findings published in Nature claims that this development is not a replacement for silicon because according to them, “silicon will maintain advantages in terms of performance, density and power efficiency.” Meaning these two technologies are expected to complement each other instead of competing with each other.

I hope you like this information and stay tuned with us to get more information like this!