Perseverance Rover to reach Mars

Mars will welcome a new guest to its land i.e. the NASA Perseverance Rover on February 18, 2021. This rover is specially designed as it features 11 metal parts that were produced by using a technique called additive manufacturing which is commonly termed as 3D printing.

This technique is quite different from normal manufacturing as rather than using forging, molding, or cutting the material from a larger block, it makes use of lasers to melt powder in successive layers to construct the part.

Not the First Rover Using 3D printing

Unique designs and traits are made possible for engineers by the 3D printing process as it allows parts that are produced are lighter, stronger, and more responsive to heat or cold. Curiosity rover was the first rover to carry 3D printed parts to Mars’s surface and has been serving on the Red Planet since 2012. 3D printed ceramic parts are fitted in Curiosity inside of its Sample Analysis at Mars Instrument.

Various Parts on Rover

3D printed components on the Perseverance are known as the secondary structures which wouldn’t cause any harm on the mission if any part fails to function as they were required to do. This step is a huge milestone in taking additional 3D printed components to Mars as it opens the door in the space industry for additive manufacturing.

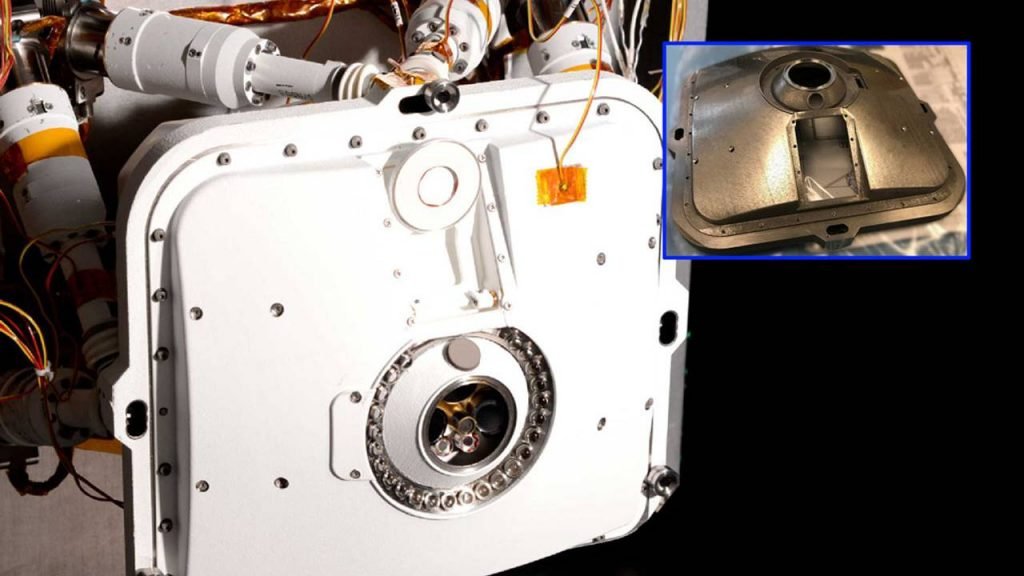

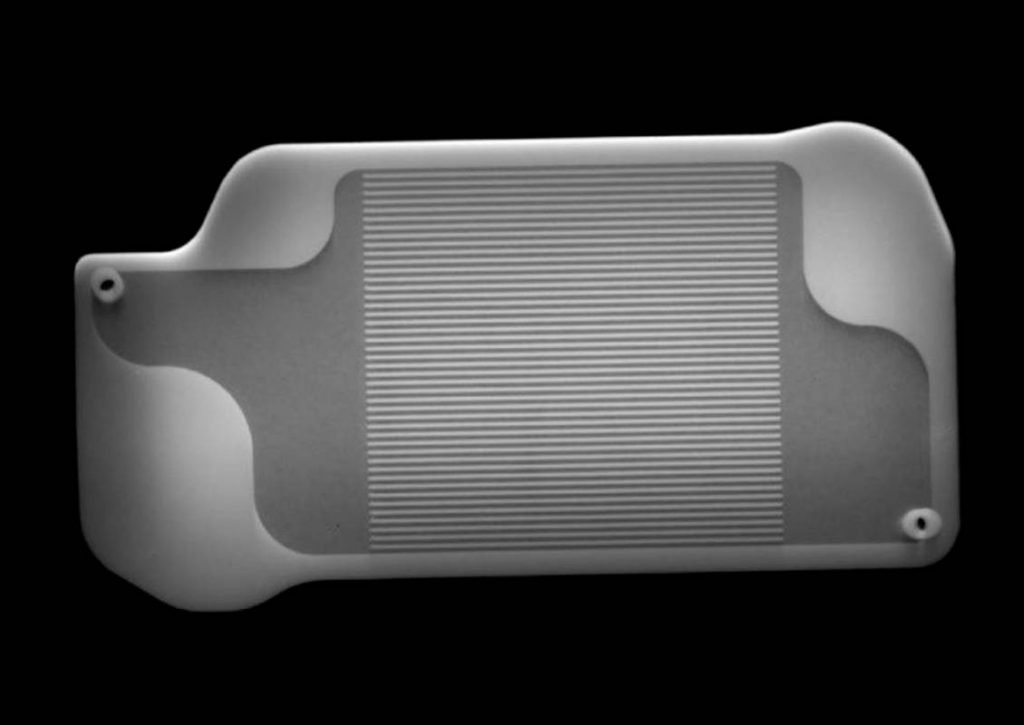

One of the 3D printed components on the Perseverance is the outer shell of the PIXIL instrument which makes use of x-ray beams directed at rocks to seek out signs of fossilized microbial life.

At the end of the seven-foot-long robotic arm attached to the rover, the instrument also shares space with other tools space aboard the rotating turret. Titanium is used to make a two-piece shell which is securing the shell to the arm’s end along with a mounting frame and two support struts. Hollow and extremely thin components were only possible due to the 3D printing technique.

3D Printing: A Beneficial Process

The parts on the rover are relatively 3 to 4 times lighter in mass if compared to the conventional approach as per NASA and these 3D printed parts are produced by a vendor called Carpenter Additive.

Researchers believe that conventional fabrication would not have achieved the high-precision pointing required, that s the reason why 3D printing processes were used to make the precision possible. Among other parts, there is also the presence of a 3D printed heat exchanger inside the MOXIE instrument.

1 Comment

Pingback: NASA’s Perseverance Rover to Mars Sends Space Sound - Craffic